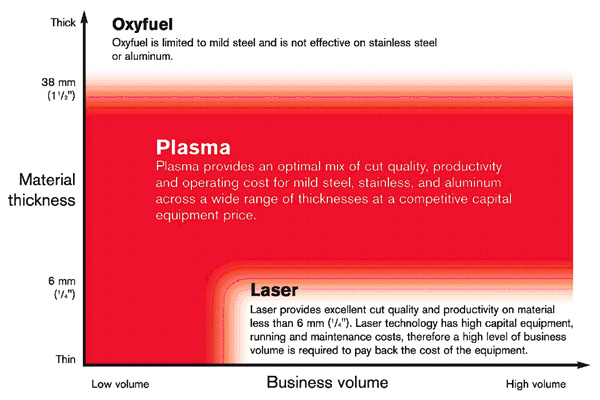

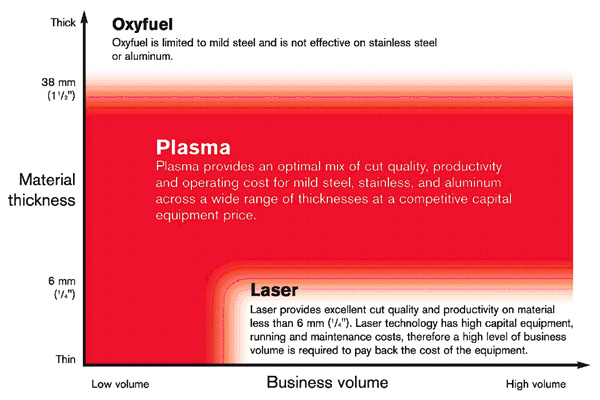

Comparison of Plasma, Oxyfuel and Lser

Plasma provides the optimal mix of cut quality, productivity and operating cost

Back to top

Plasma Capabilities Chart

Back to top

Technology Benefits

Back to top

Air Plasma: Powermax

* Note: Take care in comparison: competitors often show maximum cutting speeds rather than speeds that deliver the best cuts, as shown above. Cut speeds listed above deliver best cut quality, but cut speeds can be up to 50% faster.

** ISO 9013 is a standard that defines cut quality of thermally cut parts. The lower the range (range 1 is the lowest), the smaller the angle on the cut face. Cut angle in range 4 is better than in range 5.

Back to top

Oxygen Plasma: MAX200

* Note: Take care in comparison: competitors often show maximum cutting speeds rather than speeds that deliver the best cuts, as shown above. Cut speeds listed above deliver best cut quality, but cut speeds can be up to 50% faster.

** ISO 9013 is a standard that defines cut quality of thermally cut parts. The lower the range (range 1 is the lowest), the smaller the angle on the cut face. Cut angle in range 4 is better than in range 5.

Back to top

Plasma Advantages vs. Oxyfuel

|

Plasma Advantages vs. Laser

|

Plasma provides the optimal mix of cut quality, productivity and operating cost

| Oxyfuel | Plasma | Laser | |

| Cut quality |

|

|

|

| Productivity |

|

|

|

| Operating cost |

|

|

|

| Maintenance |

|

|

|

Plasma Capabilities Chart

| Air Plasma

|

Oxygen Plasma | LongLife Oxygen Plasma | HyPerformance Plasma | |

| System | Powermax1000

Powermax1250 Powermax1650 |

MAX200 | HT2000

HT4400 HT4001 |

HPR130

HPR260 |

| Cut Quality | Good

Some secondary operations and dross |

Better

Some secondary operations with virtually no dross |

Better

Some secondary operations with virtually no dross |

Best

Minimal to no secondary operations with virtually no dross |

| Mild steel

weldability

|

Nitriding can impair mild steel welding | Good mild steel welding

|

Good mild steel welding

|

Good mild steel welding

|

| Productivity | Good | Better

|

Better

|

Best

|

| Operating cost | Good | Good

|

Better

|

Best

|

| Consumable life | Good | Good

|

Better

|

Best

|

| Process flexibility | Good | Better

|

Better

|

Best

|

| Features | Simple bundled system with minimal options | Lower degree of features and

options

|

Lower degree of features and options | Fully featured with wide range of options |

| Application ranges | Light-duty cutting | Light- to medium-duty cutting

|

Light- to heavy-duty cutting

|

Precision cutting, light- to heavy-duty cutting |

| Price | Low | Medium

|

Higher

|

Higher

|

Technology Benefits

| Oxygen Plasma

|

LongLife

Oxygen Plasma

|

HyPerformance

Plasma

|

|

| Benefits of oxygen plasma vs. air

plasma

|

|

|

|

| Benefits of LongLife oxygen plasma vs. oxygen plasma |

|

|

|

| Benefits of HyPerformance Plasma vs. LongLife oxygen plasma |

|

Air Plasma: Powermax

|

Powermax

Entry-level single gas (air or nitrogen) cutting systems, great for duct cutting, pipe cut-off, beveling and robotic 3-D cutting. |

|

| Powermax1000 | Powermax1250 | Powermax1650 | ||

| Capacity

Mild steel |

Dross free

Production (pierce) Severance (edge starts) |

n/a

10 mm (3/8") 32 mm (1-1/4") |

n/a

10 mm (3/8") 38 mm (1-1/2") |

n/a

12 mm (1/2") 44 mm (1-3/4") |

|

Stainless steel

|

Production (pierce)

Severance (edge starts) |

10 mm (3/8")

32 mm (1-1/4") |

10 mm (3/8")

38 mm (1-1/2") |

12 mm (1/2")

44 mm (1-3/4") |

| Aluminum | Production (pierce)

Severance (edge starts) |

10 mm (3/8")

32 mm (1-1/4") |

10 mm (3/8")

38 mm (1-1/2") |

12 mm (1/2")

44 mm (1-3/4") |

| Speed*

(Mild steel) |

Optimum quality

|

10 mm (3/8")

1041 mm/m (41 ipm) |

12 mm (1/2")

991 mm/m (39 ipm) |

10 mm (3/8")

1447 mm/m (57 ipm) |

| Cut angle

|

ISO 9013 range**

|

5

|

5

|

5

|

| Weldability | Preparation required

|

Preparation required | Preparation required | |

| Process gases by

material

(Plasma/ shield) |

Mild steel

|

Air | Air

|

Air

|

|

|

Stainless steel

|

Air, N

2

|

Air, N 2 | Air, N 2 |

| Aluminum | Air, N

2

|

Air, N

2

|

Air, N

2

|

|

| Process amps

|

Not all processes available for all

materials

|

20-60 | 25-80

|

30-100

|

* Note: Take care in comparison: competitors often show maximum cutting speeds rather than speeds that deliver the best cuts, as shown above. Cut speeds listed above deliver best cut quality, but cut speeds can be up to 50% faster.

** ISO 9013 is a standard that defines cut quality of thermally cut parts. The lower the range (range 1 is the lowest), the smaller the angle on the cut face. Cut angle in range 4 is better than in range 5.

Back to top

Oxygen Plasma: MAX200

|

MAX200

Entry-level oxygen cutting system, great for often-changing cutting requirements and production schedules. A proven production cutting system with an attractive initial capital cost. |

|

| MAX200 | ||

| Capacity

Mild steel |

Dross free

Production (pierce) Severance (edge starts) |

25 mm (1")

25 mm (1") 50 mm (2") |

|

Stainless steel

|

Production (pierce)

Severance (edge starts) |

25 mm (1")

50 mm (2") |

| Aluminum | Production (pierce)

Severance (edge starts) |

25 mm (1")

50 mm (2") |

| Speed*

(Mild steel) |

Optimum quality

|

12 mm (1/2")

2159 mm/m (85 ipm) |

| Cut angle

|

ISO 9013 range**

|

4 - 5

|

| Weldability | Ready to weld | |

| Process gases by

material

(Plasma/ shield) |

Mild steel

|

Air/Air, O

2/Air,

N 2, CO 2 |

|

|

Stainless steel

|

Air/Air, N

2/Air,

N 2/CO 2, H35/N 2 |

| Aluminum | Air/Air, N

2/Air,

N 2/CO 2, H35/N 2 |

|

| Process amps

|

Not all processes available for all

materials

|

40-200

beveling (200) |

* Note: Take care in comparison: competitors often show maximum cutting speeds rather than speeds that deliver the best cuts, as shown above. Cut speeds listed above deliver best cut quality, but cut speeds can be up to 50% faster.

** ISO 9013 is a standard that defines cut quality of thermally cut parts. The lower the range (range 1 is the lowest), the smaller the angle on the cut face. Cut angle in range 4 is better than in range 5.

Back to top